- Slot Cutting Machine In India Rupees

- Slot Cutting Tools

- Slot Cutting Machine In India Mumbai

- Cutting Slots In Wood

Channel Cutter Wall Chaser Machine with Twin Blade Rs 7,200/ Piece(s) Get Latest Price The powerful, handy and robust masonry channel cutter - wall chaser is designed for quick and precise installation slots in brick, plaster, cement and similar building materials. Slot Wedge Making Machine Rs 2.65 Lakh/ Unit Get Latest Price Slot Wedge Making Machine is used to make slot wedge, dovetail strips, fiberglass strips, edge rounded strips, profiling, rounding on wood, press board, fiberglass or insulation sheets or any other similar material.

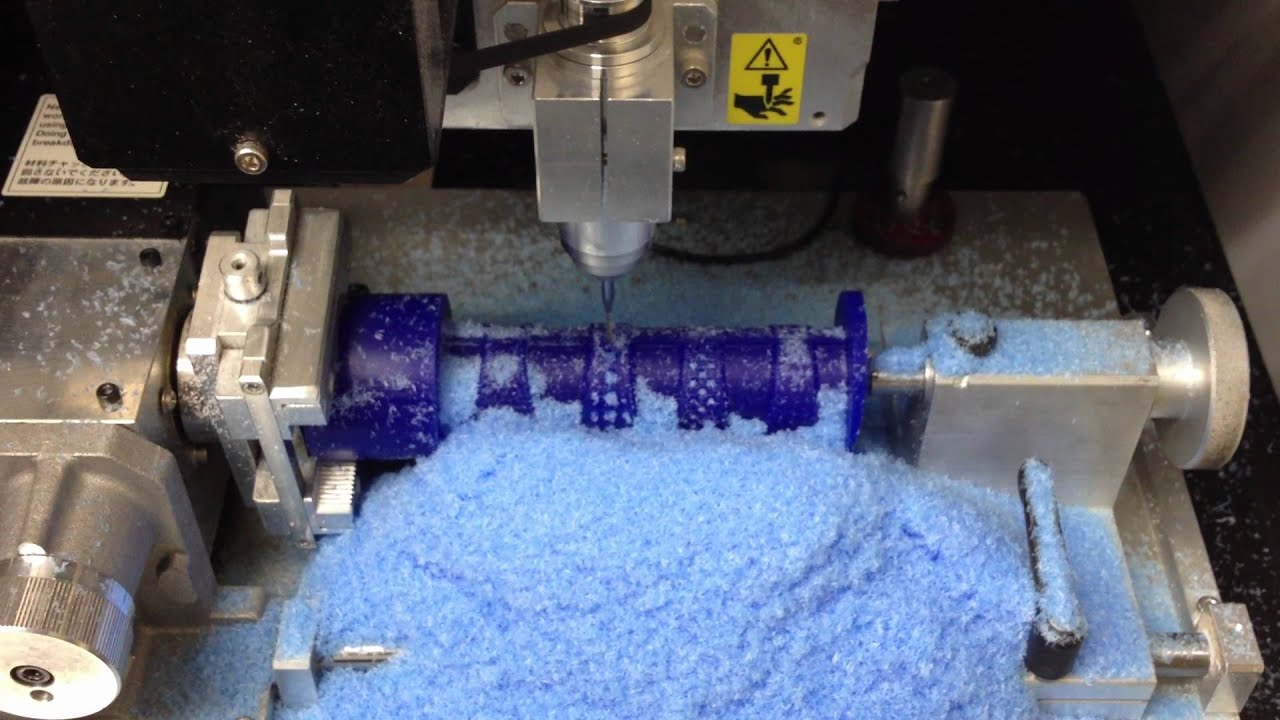

We are successfully engaged in the production and distribution of highly acclaimed Pipe Slotting Machine in the industry. Our M.S. Pipe/ Pvc Pipe Slotting Machine is backed with all the modern features that make it very effectual in the area of application. It is extensively used for cutting and slotting pipes in the desired shapes as required by the customers. These slotting machines are remarkable for their operation friendly features. In addition to this they are also noted for the barest minimum consumption of fuel in their usages. We own quality pipe slot machine, which is one of the largest in India that has the lowest electricity consumption along with a specific technique. It reduces the cost of the slotting in its kind, with a good speed of production also. Apart from that, we are counted as one of the most famed M.S. / Pvc Pipe Slotting Machine Manufacturers in the domestic market.Generally the slotting machines available in the market slot the 6 meter long pipe in three parts whereas the machine developed by us does the slotting in two parts only. Thus, it remarkably reduces the cost of slotting as well as per pipe slot time.

We also manufacturer pipe slotting machine to cut slot 6 meter long pipe in one part. We can make pipe slotting machine as per your requirement.

Range

- Semi Automatic Pipe Slotting Machine

- Fully Automatic Pipe Slotting Machine

We are a leading shaper machine manufacturer that caters to all industrial needs with advanced technology to shape materials accurately at faster rates. The popular Shaper Machines is effective working type of shaper cutting tool uses linear relative motion. It has the ram moves backwards and forwards across the workpiece to finish into flat surfaces. Shaper machines surface may be horizontal, vertical, inclined, concave/convex, angular that make grooves, slots, keyways, etc. Thus these machine tools easily attains any desirable shape. The Horizontal shaper type is the common arrangement to get plane surfaces of a work-piece. The ram in horizontal axis movement is converted into reciprocating movement to achieve required successful cutting operation.

Shaper machine works on a single return crank mechanism that provides tool reciprocating motion. It has a base, column, saddle, clapper box, cross rail, reciprocating ram holding the tool adjustable for cutting stroke, tool head at front of the ram etc. In its mechanism, all these parts provide great flexibility in the work easily held.

The working principle has the cutting work performed during stroke that forwards direction when work job is hold firmly on the table.

The machine offers higher load carrying capacity and great efficiency. Shaper machine provides flexibility and act as a convenient cutting tool to achieve wanted shape when cutting the work piece. In short, shaper machine consists of a tool reciprocal ram used for performing the cutting operation during the forward stroke. The ram adjusted so well for the strokes to machine straight flat surfaces.

If have any query regarding shaper machine then enquire us.

Quite robust and Rigid Construction to Avoid Vibrations.

Machine is made with Graded casting which is properly seasoned for At least 6 to 8 Months

Highly accurate as Per IS Standards (IS: 2308: 1989)

Quick Return Movement to save idle time

Rocker arm Mechanism Operation

All Gears are made of EN series Steel, Properly cut on Hobbing and Gear shaper Machines.

Gears in the machine are properly Hardened and lapped.

Machine and Gear Box is filled with C-oil

2 years Warranty against any Manufacturing Faults.

Slot Cutting Machine In India Rupees

PRICE: ON REQUEST

Slot Cutting Tools

Order by Phone

+91-9878609009

Shipping Information Usually dispatched With In business days.

Slot Cutting Machine In India Mumbai

| Technical Specifications of Cone Pully type & ALL Geared Type | ||||

|---|---|---|---|---|

| MODEL | DHS – 12 | DHS – 18 | DHS – 24 | DHS – 30 |

| RAM | ||||

| Length of Ram Stroke | 12” / 305mm | 18”/ 457mm | 24”/610mm | 30”/762mm |

| Length of Ram | 26” / 660mm | 40.5″ /1029mm | 50”/1270mm | 58”/1473mm |

| Length & Width of Ram Bearing | 26 X 7”/660 X 178mm | 28.5″ X 9”/724 X 229mm | 33 X 11.5”/838 X 292mm | 39 x 13.5″ /990 x 317mm |

| Max & Min Distance from Table to Ram | 10X 1”/254 X25 mm | 15 X 1”/381 X 26mm | 18 X 3”/457 X 89mm | 19 x 3”/483 x 76mm |

| TABLE | ||||

| Working Surface Of Table | 12 x 8”/305 x 203mm | 18 X 11.5 ”/457 X 292mm | 24 X 14”/610 X 356mm | 30 x 15”/762 x 361mm |

| Max Table Travel Horizontal | 16.5 ”/419 mm | 18”/457mm | 24”/610mm | 30”/762mm |

| Max Table Travel Vertical | 9”/ 229 mm | 13”/330mm | 15”/381mm | 17.5 “/444mm |

| Angular Movement Of Table | 60’L 60’R | 60’L 60’R | 60’L 60’R | 60’L 60’R |

| BASE | ||||

| Length & Width Of Base | 37 X 18”/940 X457mm | 50X 17.5”/1270X 444mm | 64 X 23”/1626 X 585mm | 72 X 26”/ 1880 X 660mm |

| Length Of Main Slide Base | 23” / 584mm | 29”/736mm | 36”/914mm | 41”/2565mm |

| TOOL HEAD | ||||

| Max.Vertical Travel Of Tool Slide | 5” / 127mm | 5.5 ”/139mm | 5.5 ”/146mm | 5.5 ”/146mm |

| Max.Swivel Of Tool Head | 60’L 60’R | 60L’ 60’R | 60’L 60’R | 60’L 60’R |

| SPEED & FEEDS | ||||

| Range Of Ram Speed In Cone Pulley | 3 | 4 | 3 | |

| Range OF Ram Speed In All Geared | 4 | 4 | 4 | |

| Die Of Clutch Pulley | 9.5″ / 241mm | 12”/305mm | 12”/305mm | 14”/355mm |

| Die Of Motor Pulley | 2.5 ” / 64mm | 2 3/4″/70mm | 2 3/4”/70mm | 2 3/4”/70mm |

| Stroke Per Minutes | 30,60,90 | 16,32,64,96 | 12,24,48,72 | 8,16,32,48 |

| Range Of Table Feed Per Stroke Of Ram | 0.009”/0.229mm | 0.009”/0.229mm | 0.009”/0.229mm | 0.009”/0.229mm |

| Range Of Tool Head Feed | Hand Feed | Hand Feed | Hand Feed | Hand Feed |

| SPECIFICATION OF VICE | 5”/127mm | 8”/203mm | 12”/304mm | 131/2”/336mm |

| OVERALL DIMENSIONS & WEIGHT | ||||

| Length | 48”/1219mm | 62”/1580mm | 78”/1981mm | 88”/2150mm |

| Width | 30”/762mm | 37”/940mm | 43”/1092mm | 48”/1219mm |

| Heigh | 54”/1371mm | 55”/1400mm | 63”/1600mm | 62”/1550mm |

Cutting Slots In Wood

| MODEL | DHS – 32 | DHS – 36 | DHS – 40 |

| RAM | |||

| Length of Ram Stroke | 32”/813mm | 36”/914mm | 40”/1060mm |

| Length of Ram | 60”/1524mm | 68”/1727mm | 74”/1880mm |

| Length & Width of Ram Bearing | 41 X 13.5”/1041 X 343mm | 45 X 13.5”/1143X 336mm | 47 X 13.5”/1194 X 336mm |

| Max & Min Distance from Table to Ram | 18 X 4”/457 X 102mm | 20 X 4”/508 X 102mm | 22 X 4”/559 X 102mm |

| TABLE | |||

| Working Surface Of Table | 32 X 16”/813 X 406mm | 36 X 17”/914 X 432mm | 40 X 18”/1016 X 457mm |

| Max Table Travel Horizontal | 32”/813mm | 36”/914mm | 42”/1067mm |

| Max Table Travel Vertical | 18”/457mm | 20”/508mm | 22”/559mm |

| Angular Movement Of Table | 60’L 60’R | 60’L 60’R | 60’L 60’R |

| BASE | |||

| Length & Width Of Base | 74 X 26”/1880 X 660mm | 82 X 28/2082 X 711mm | 84 X 30”/2134 X 762mm |

| Length Of Main Slide Base | 42”/1069mm | 47”/1194mm | 50”/1270mm |

| TOOL HEAD | |||

| Max.Vertical Travel Of Tool Slide | 8”/203mm | 9”/228mm | 10”/254mm |

| Max.Swivel Of Tool Head | 60’L 60’R | 60’L 60’R | 60’L 60’R |

| SPEED & FEEDS | |||

| Range Of Ram Speed In Cone Pulley | 3 | 3 | 3 |

| Range OF Ram Speed In All Geared | 4 | 4 | 4 |

| Die Of Clutch Pulley | 14”/356mm | 16”/406mm | 14”/356mm |

| Die Of Motor Pulley | 2 3/4”70mm | 2 3/4”70mm | 2 3/4”70mm |

| Stroke Per Minutes | |||

| Range Of Table Feed Per Stroke Of Ram | 0.009”/0.229mm | 0.009”/0.229mm | 0.009”/0.229mm |

| Range Of Tool Head Feed | Hand Feet | Hand Feet | Hand Feet |

| SPECIFICATION OF VICE | 131/2”/336mm | 15”/381mm | 16”/406mm |

| OVERALL DIMENSIONS & WEIGHT | |||

| Length | |||

| Width | |||

| Heigh |